Let customers speak for us

Need help finding your future board?

You can contact us:

- Through our chat

- By email

- At our showroom in Anglet

- Or by appointment

Our team of enthusiasts is available daily.

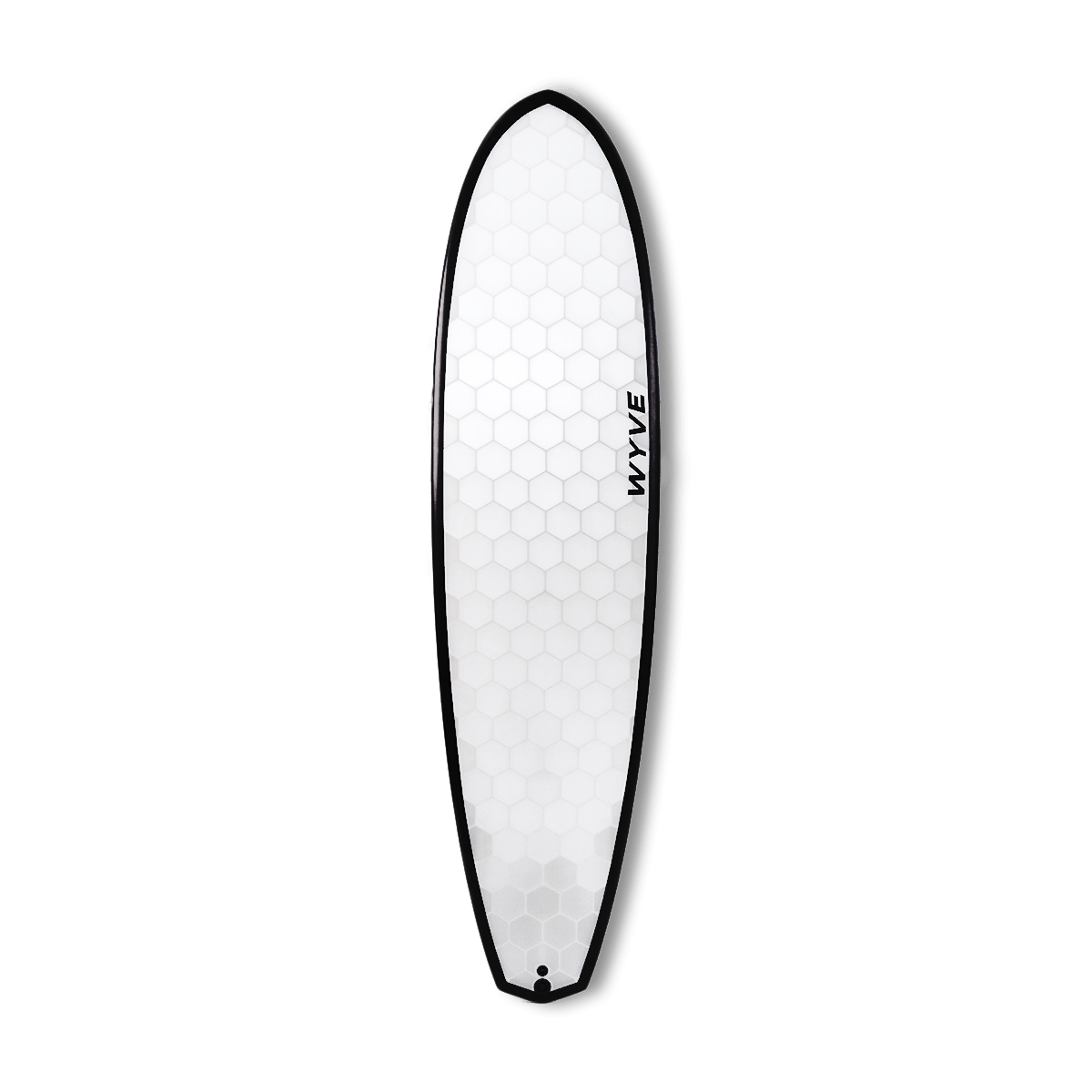

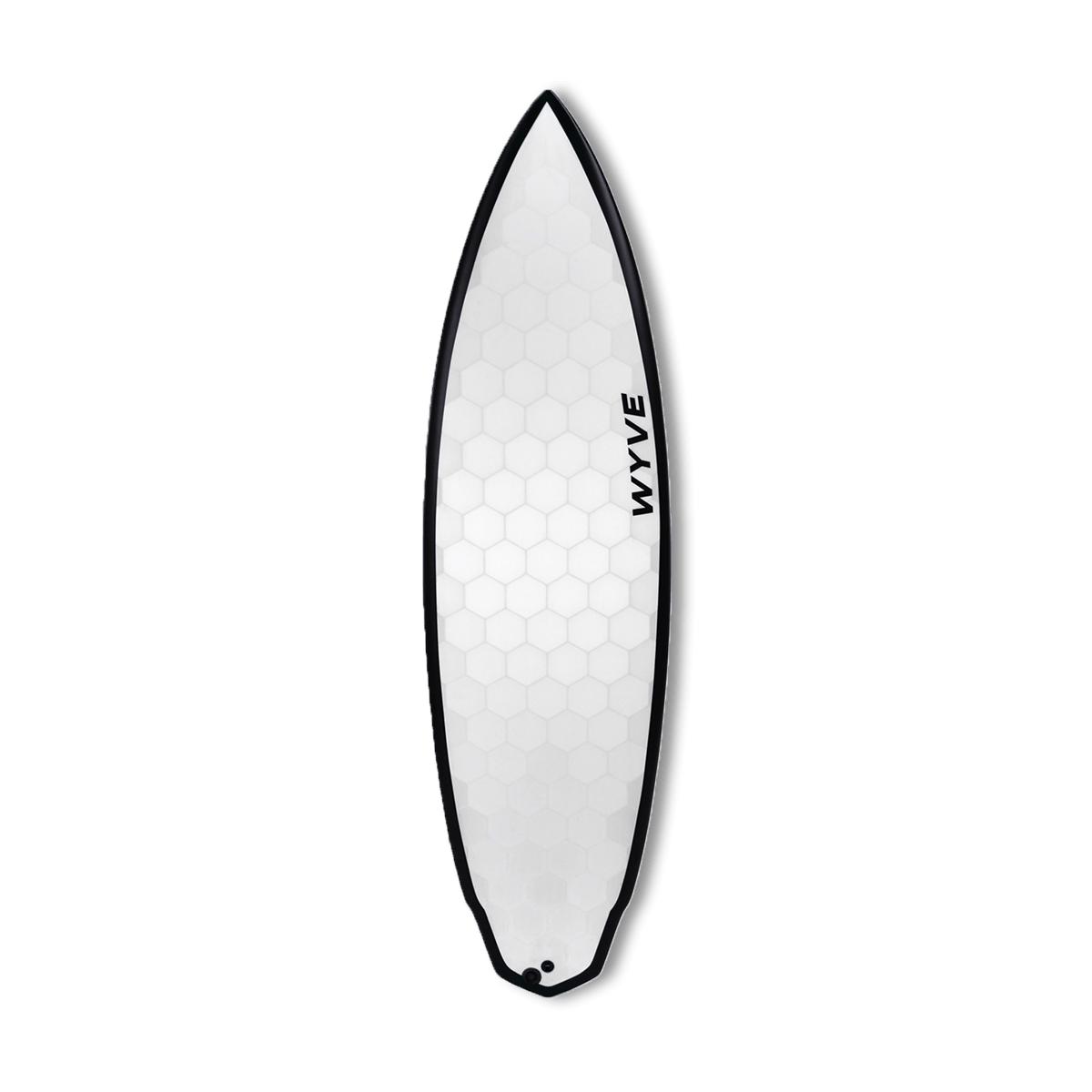

Surfing a WYVE board means choosing to explore a new dimension of surfing. Thanks to 4DCore technology, the inside of the board has variable geometry to push the limits of surfing performance.

The engineers on the WYVE team work every day to offer you the best surfing experience. The board of the future combines performance, resistance and eco-design.

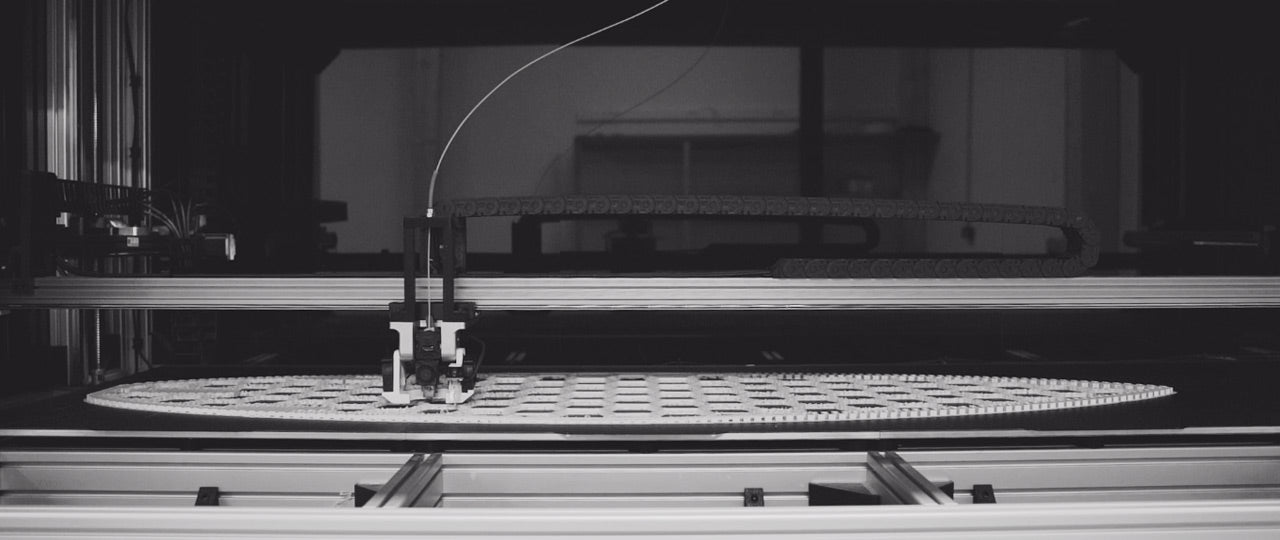

STATE-OF-THE-ART TECHNOLOGY

HiGH-END TECHNOLOGY

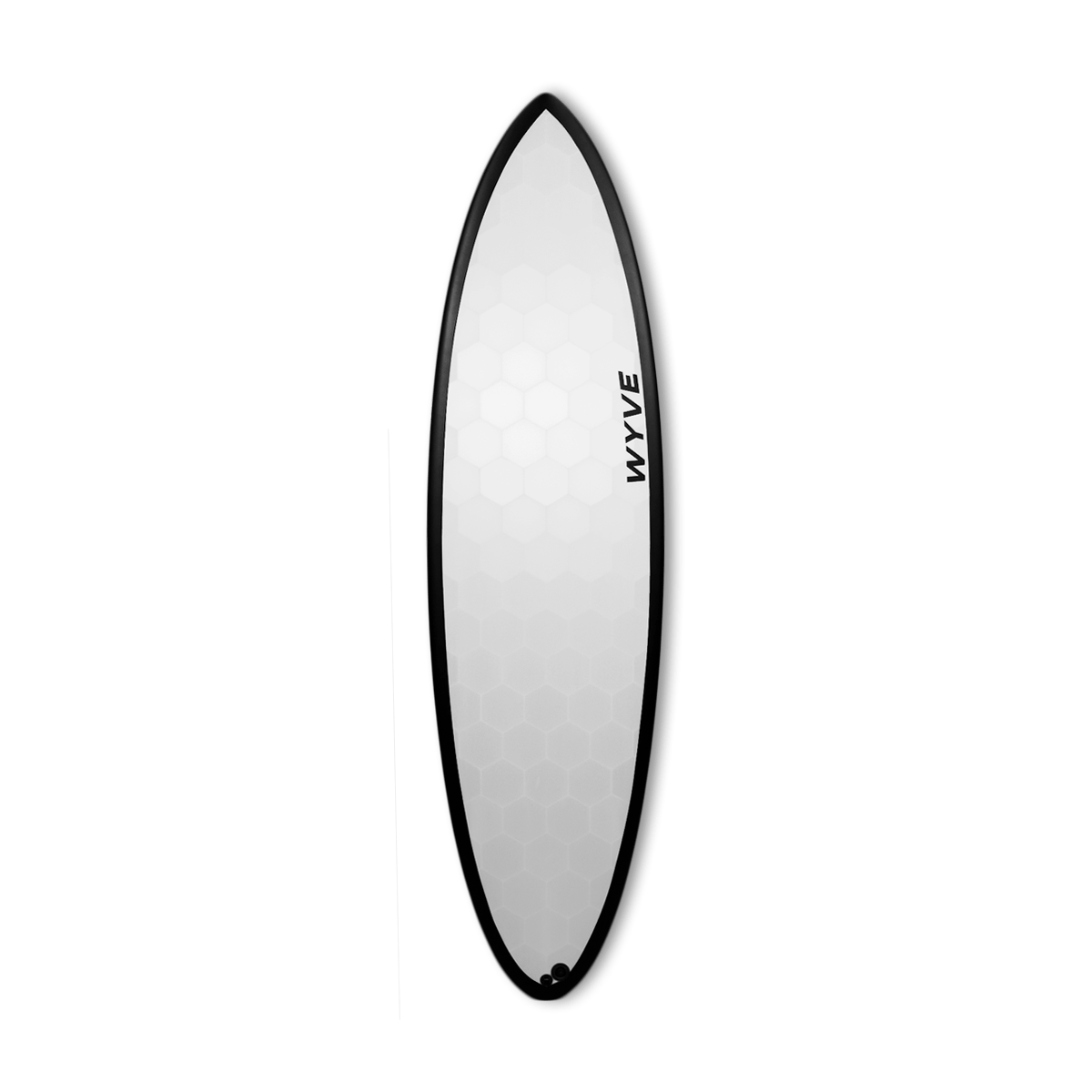

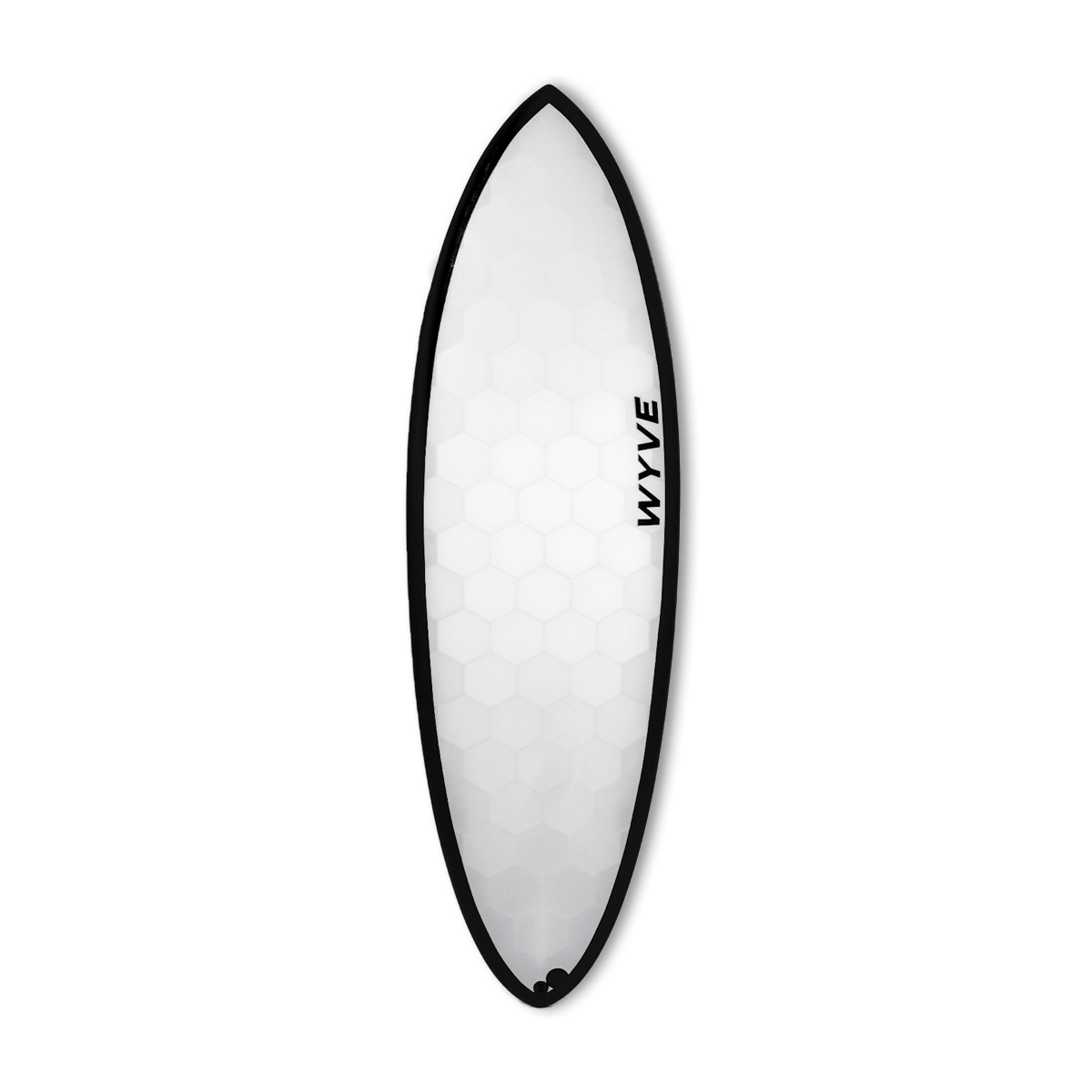

Each board is made-to-order, in our mini-factory!

From design to finishing, including 3D printing, all stages are carried out by our technicians, engineers and shapers. This patented manufacturing process is the result of 3 years of research and development.

FEEL THE DIFFERENCE.

Surf with pride. Your WYVE board combines the best of technology and sustainable design.

Follow us on Instagram

@wyvesurf

Bring your

brand to life.

brand to life.