OUR GOAL : get the most out of each wave

In the development of 4DCore technology, we have identified the two main parameters to take the most out of your surfing session, regardless of the level: optimized flexibility and paddling ease.

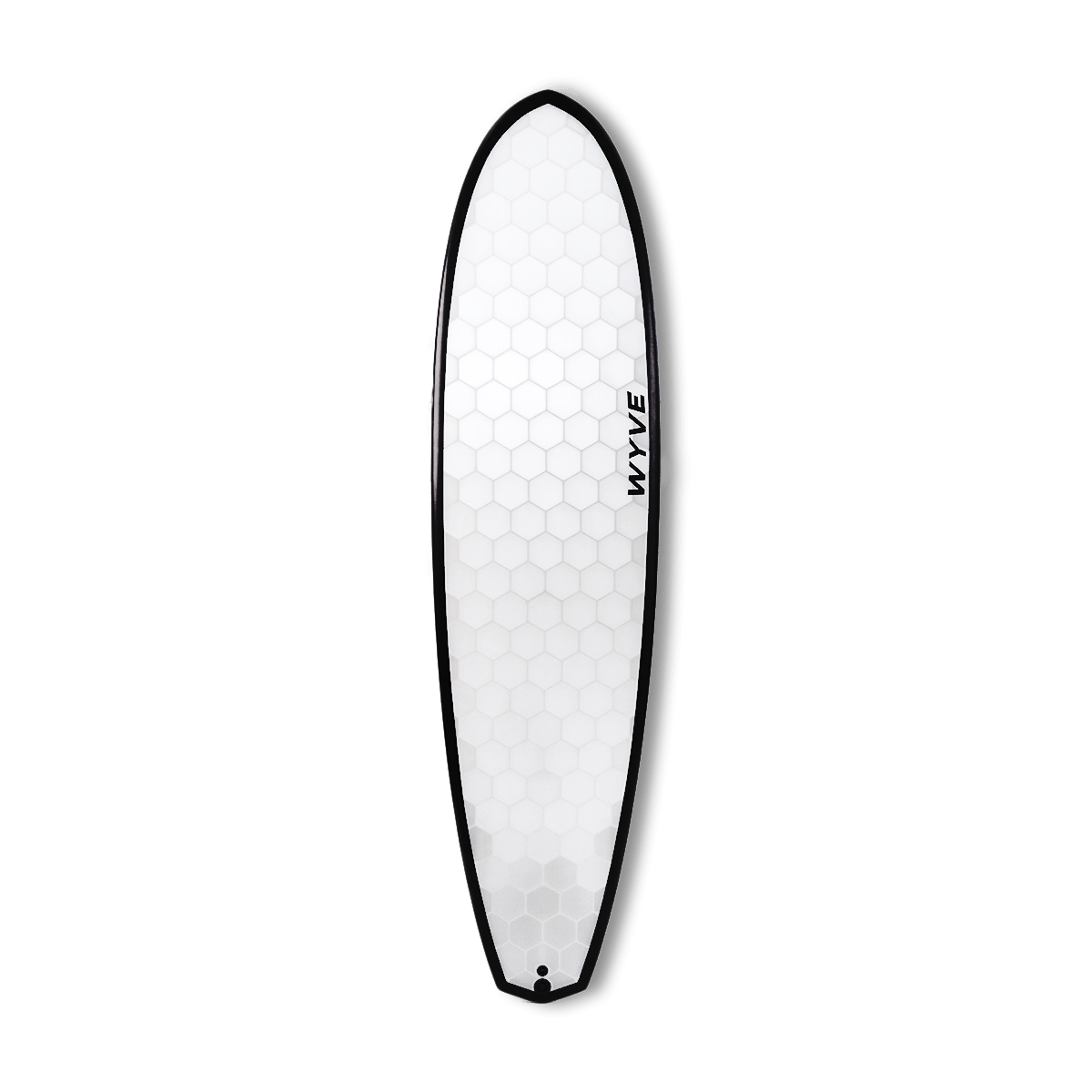

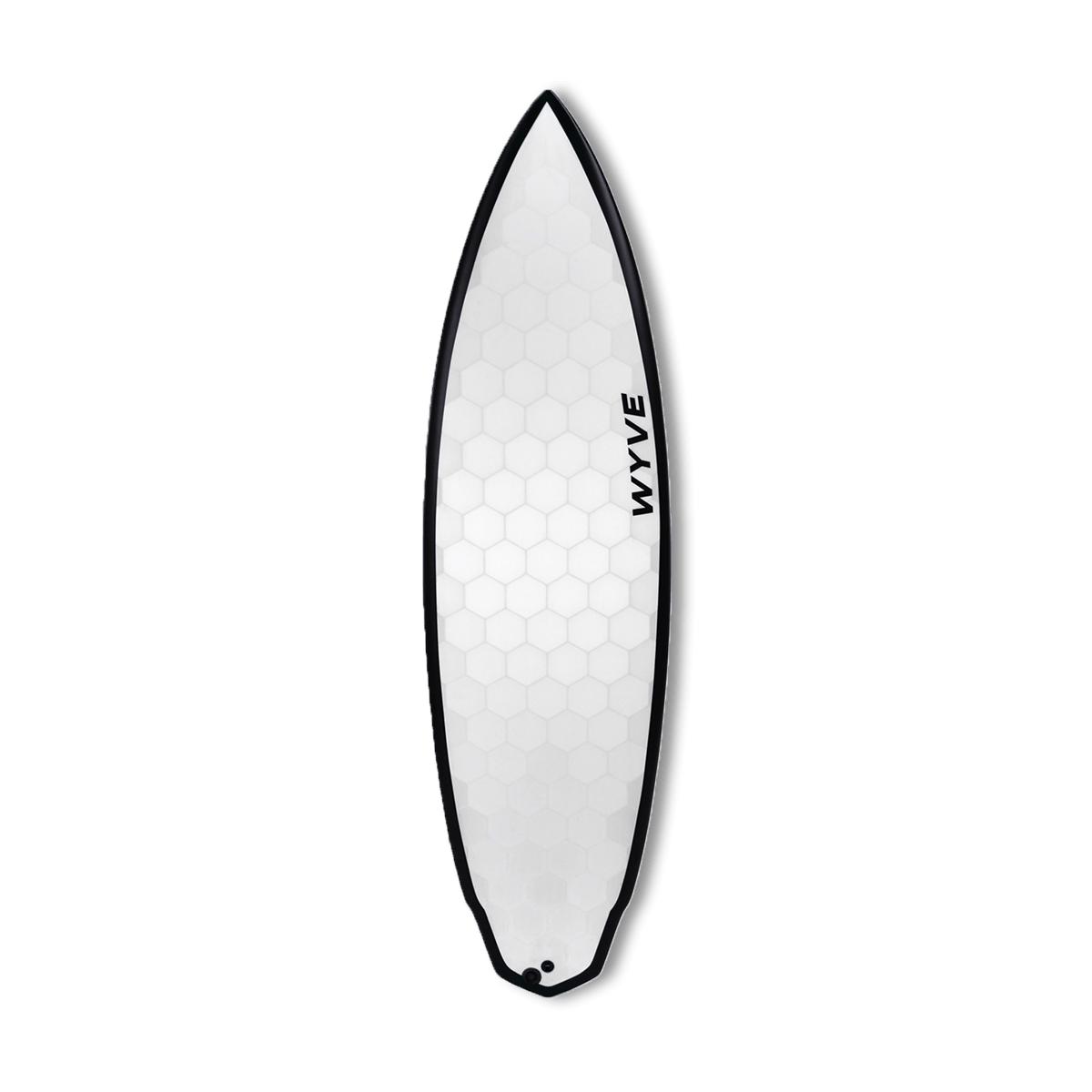

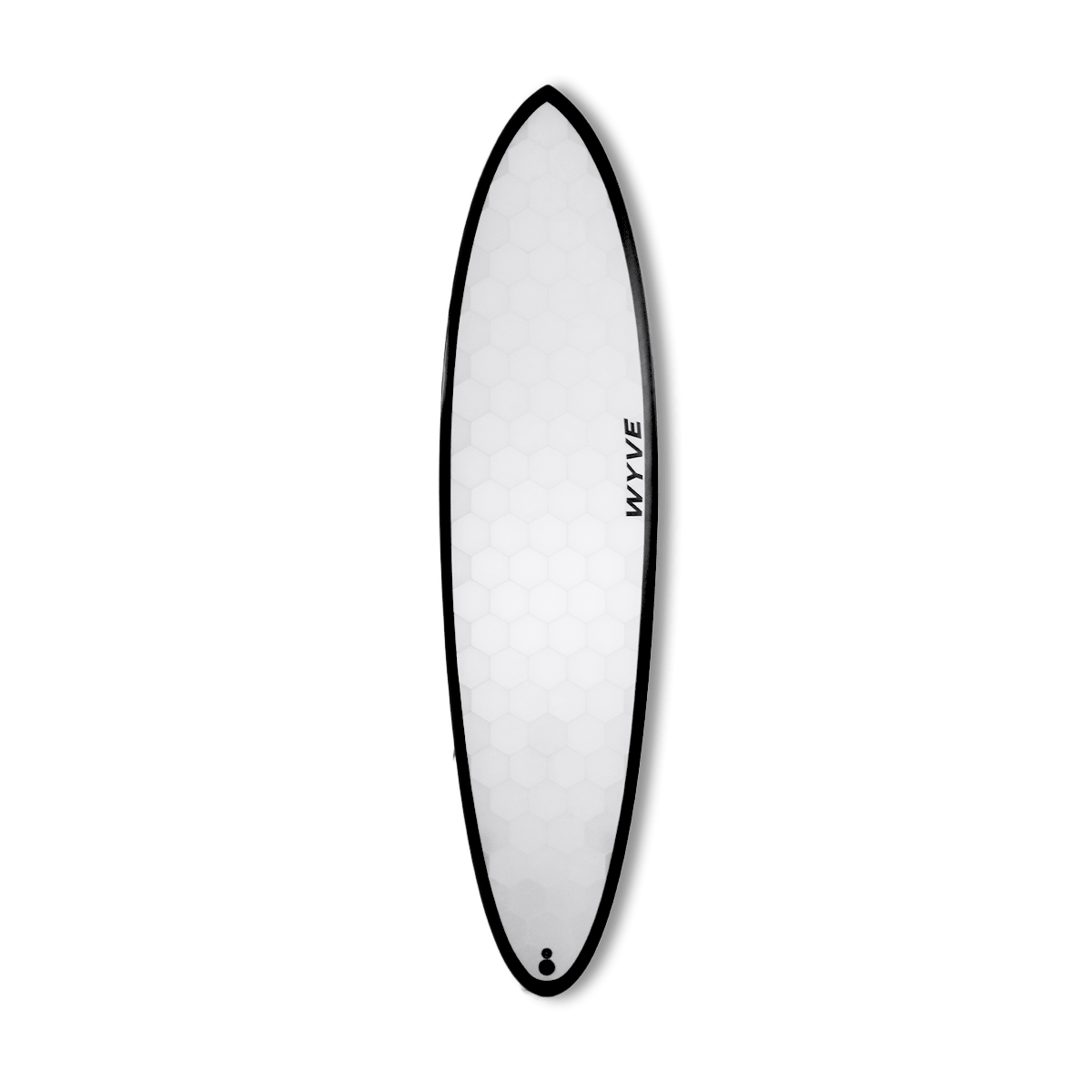

Thanks to the 4DCore structure, the density of the hexagons is variable over the entire length of the board . The flexibility is therefore adapted for each model, depending on the waves surfed.

Thanks to the hollow and less dense structure at the nose, buoyancy is increased under the shoulders to simplify paddling.

You save your energy for the waves.