FAQ

Order

Need help with your order, you can also contact us via chat or via our dedicated page.

You can pay for your order online by credit card (Visa, Mastercard, American Express).

Yes, you can choose the ALMA payment method to pay in 2 or 3 installments from 100 euros. The first payment is made upon ordering, followed by monthly payments.

If your board is not available in stock, you can pre-order it. In this case it takes 60 days to receive the board at your home.

Construction

If you want to know more about our 4D Core construction , click here:

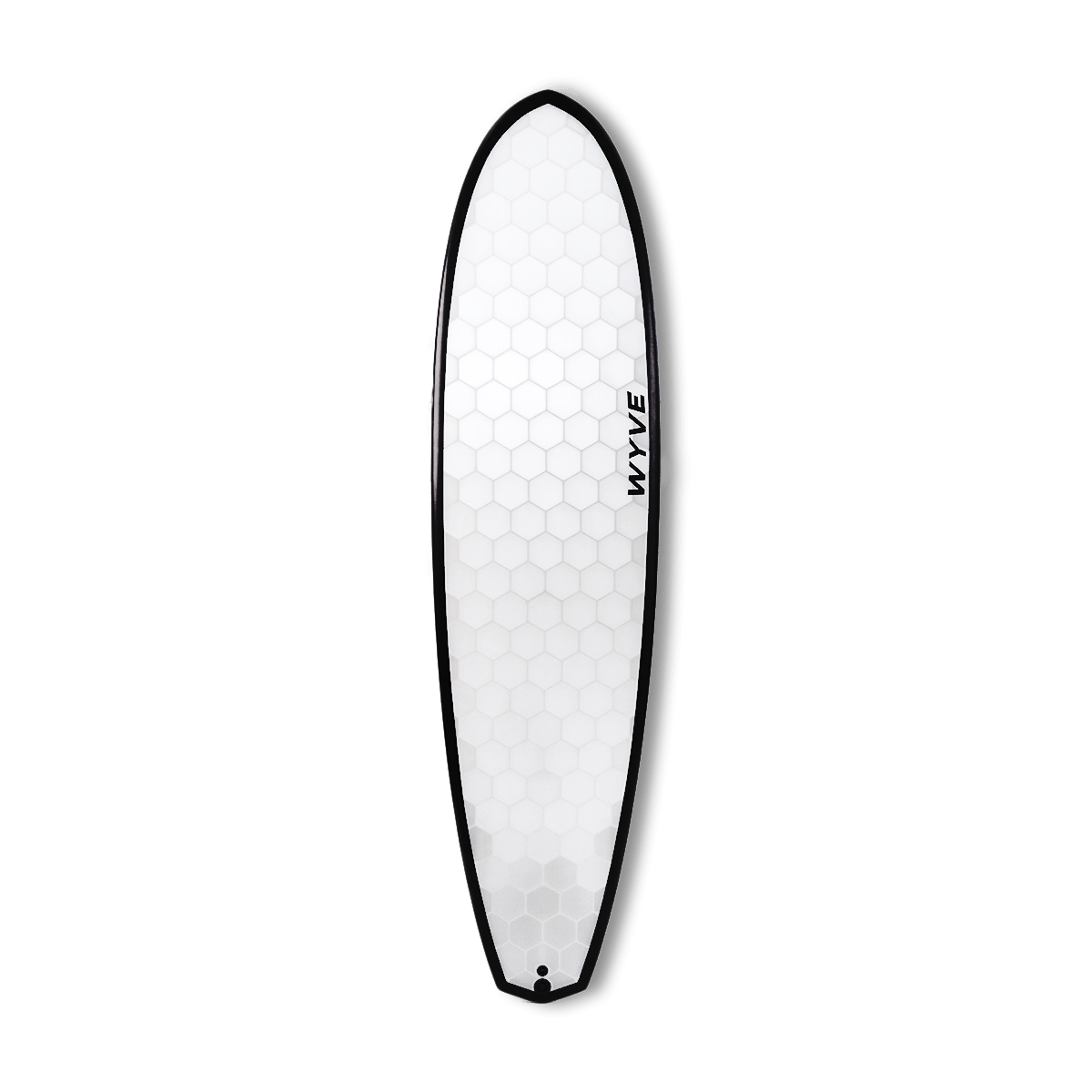

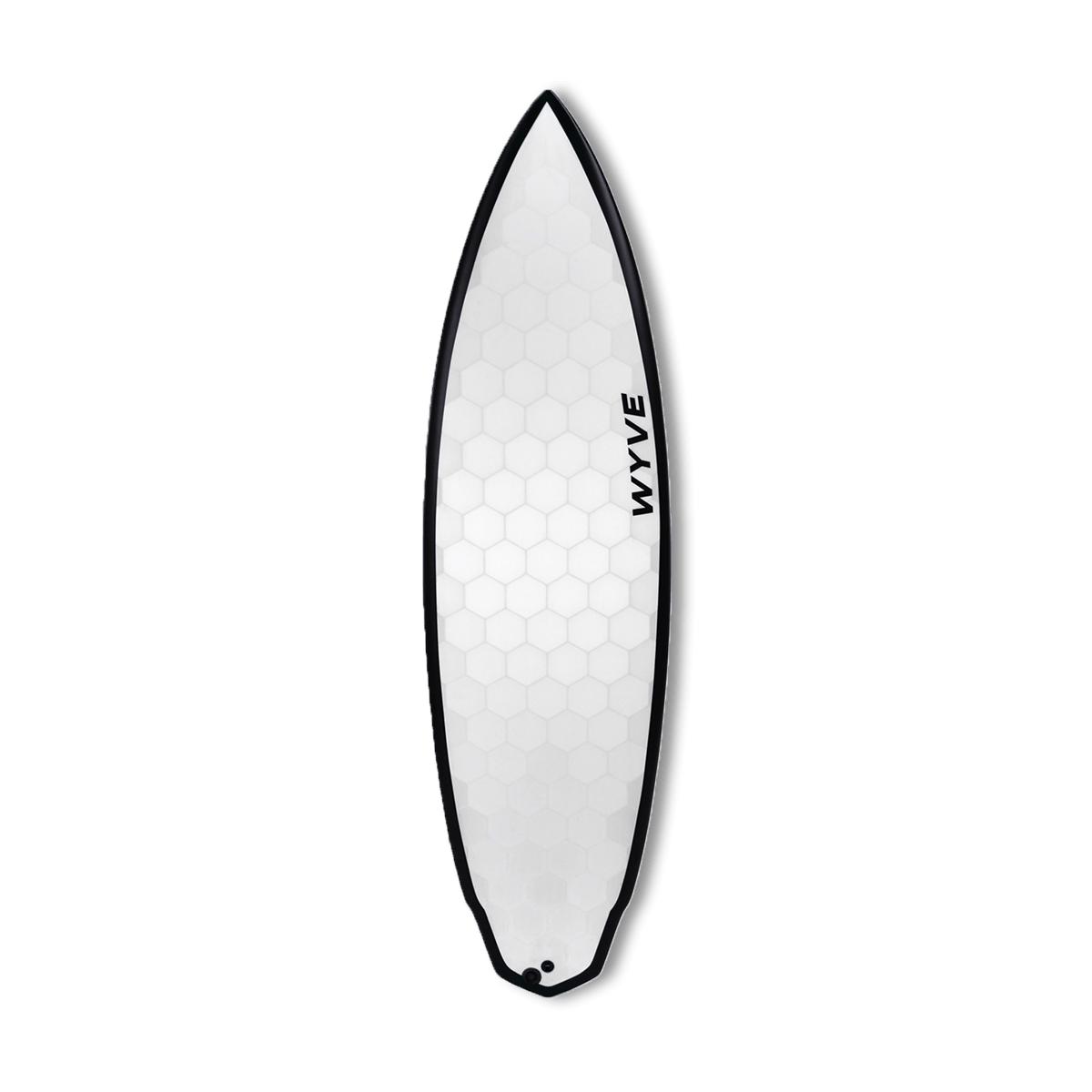

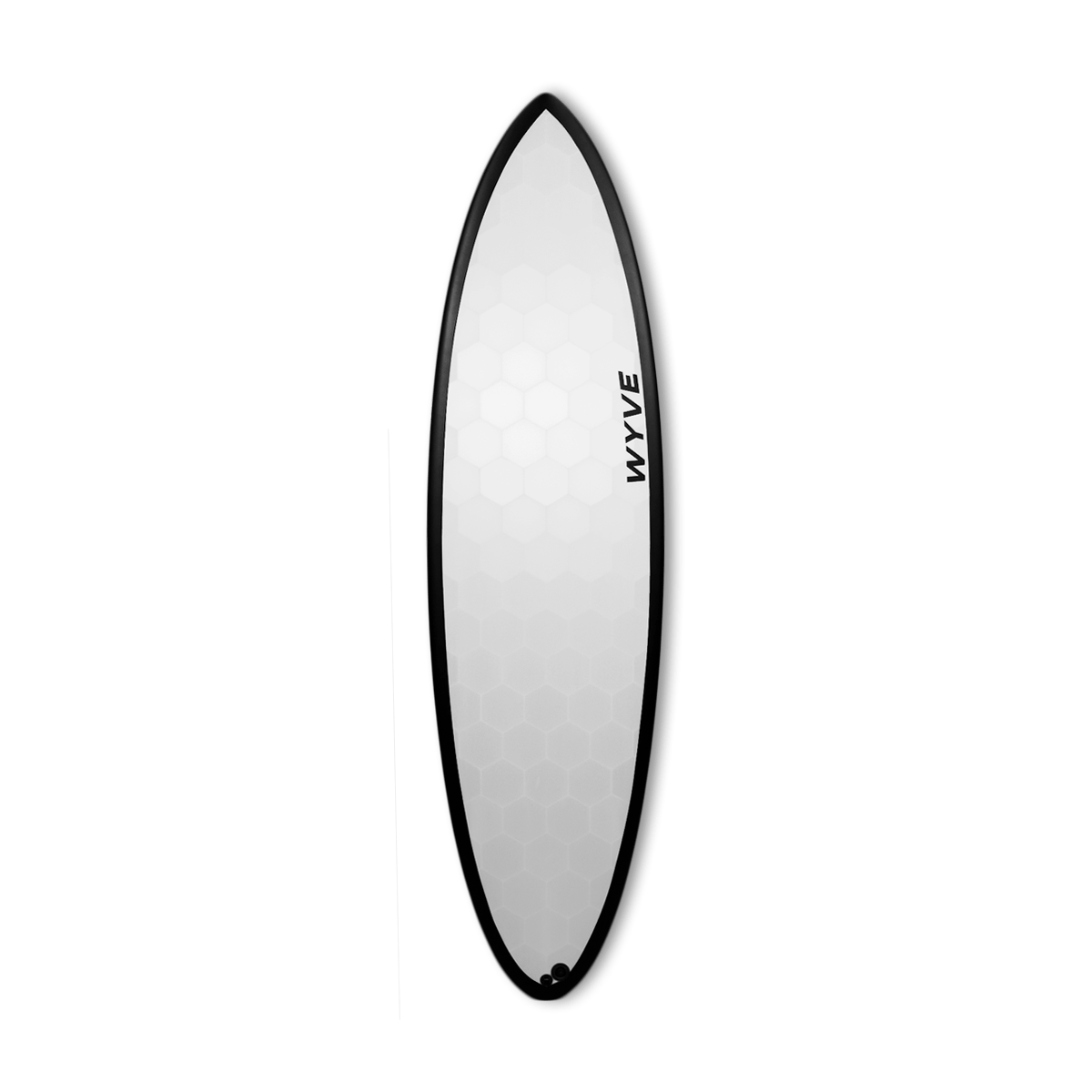

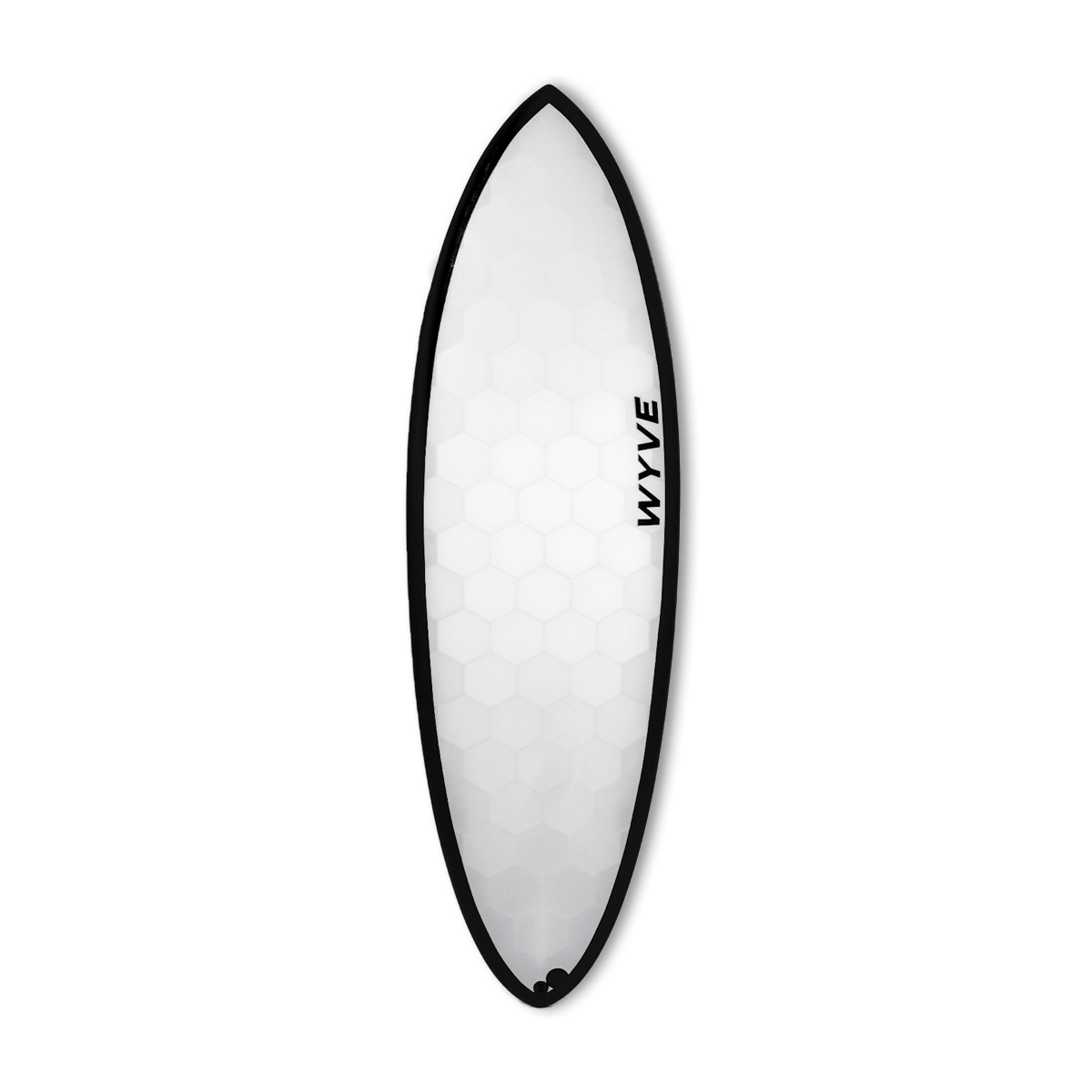

Wyve boards are manufactured using revolutionary 3D printing technology, offering an internal PLA structure that makes them stronger, lighter and more durable than traditional foam boards.

Yes, our boards are designed to be lightweight while maintaining strength and performance.

Thanks to their increased strength, ease of repair and light weight, Wyve boards tend to have a longer lifespan than traditional boards.

The internal PLA structure provides increased strength, remarkable lightness and ease of repair, making Wyve boards a solid choice for all surfers.

We offer a range of boards suitable for different types of waves. Check out our selection to find the one that suits your local conditions.

Yes, we are working on a recycling process aimed at reusing 100% of the internal plastic structure of our boards, as well as 3D printing scraps.

Wyve boards are among the lightest on the market. All board weights are indicated on our online store and are subject to a tolerance of plus or minus 6%.

Repair & Maintenance

Repairing a Wyve board is simple thanks to our perforated internal structure. For small repairs, use a product like Solarez. For more extensive repairs, consult a professional shaper.

Use the tool provided with the board to open the valve on the tail. Once opened, water will flow naturally thanks to the connectivity between the hexagons. After draining, make the necessary repairs and screw the valve back on.

Use the valve located on the tail of the board, supplied with your Wyve board, to drain the water. Our internal PLA structure allows water to drain naturally.

Yes, we can re-print and re-assemble damaged parts of the internal PLA structure.

Custom order

Want a custom board! You can contact us

Yes, we offer customization options for board decoration. Contact us to discuss your preferences.

The manufacturing time for a custom Wyve board varies depending on demand. Contact us for specific information.

Use this text to answer questions in as much detail as possible for your customers.

About

You can purchase our boards online via our website or by visiting our authorized resellers.

The cross between Wave and Hive forms WYVE: the new wave for the boards of the future.

All Wyve surfboards are made in France in our factory in Anglet

Want to join our team, it's very simple, just fill out our form.

Deliveries

Good news ! we send surfboards all over the world. To find out everything, click here

We ship surfboards and accessories with different carriers, mainly DHL and/or Geodis. Our packaging is reinforced to avoid any damage during transport.

For deliveries in mainland France, allow approximately 2 to 3 working days. Delivery times may be longer for Corsica, mountainous areas or islands. Note that deliveries are made Monday to Friday, unless otherwise stated.

After confirming your order, you will receive a confirmation email. Once the board has been shipped by our logistics partner, you will receive an SMS and an email. In some cases, the carrier will invite you to make an appointment for delivery during a defined time slot.

You can also choose to collect the board from the carrier's premises. It is essential to check the condition of the goods in the presence of the delivery person and to ensure that the fins are present.

For accessory orders in France and Europe, they are generally processed the same day and delivered in less than 3 days to your home.