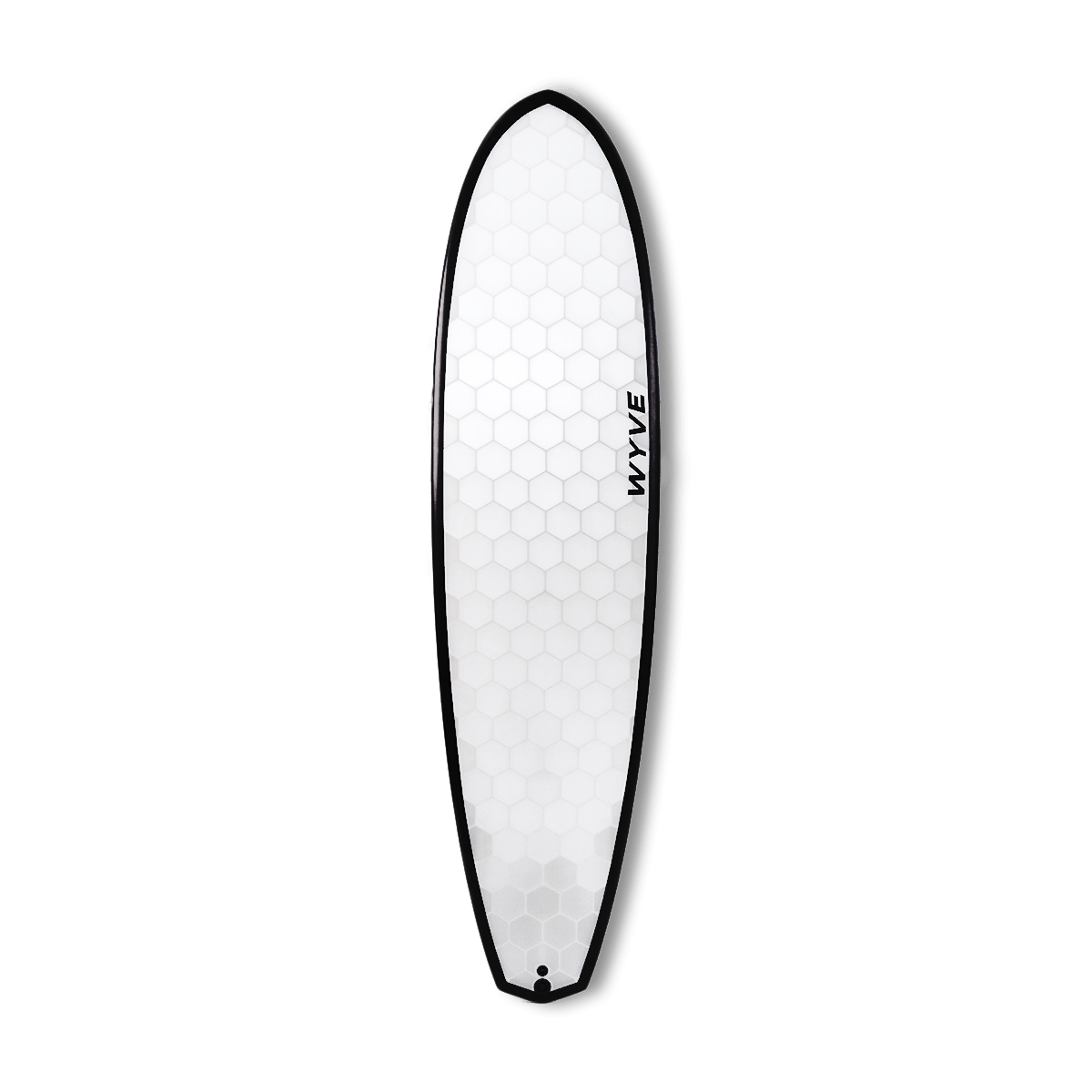

Designed to minimize the impact on manufacturing

Our choice of materials is based on a life cycle analysis to minimize the carbon footprint per board.

60% of the materials used are bio-sourced.

This reduces CO2 emissions per board by 40% (compared to a polyurethane board).

This gain is even more significant if we take into account the extended lifespan of the WYVE board.

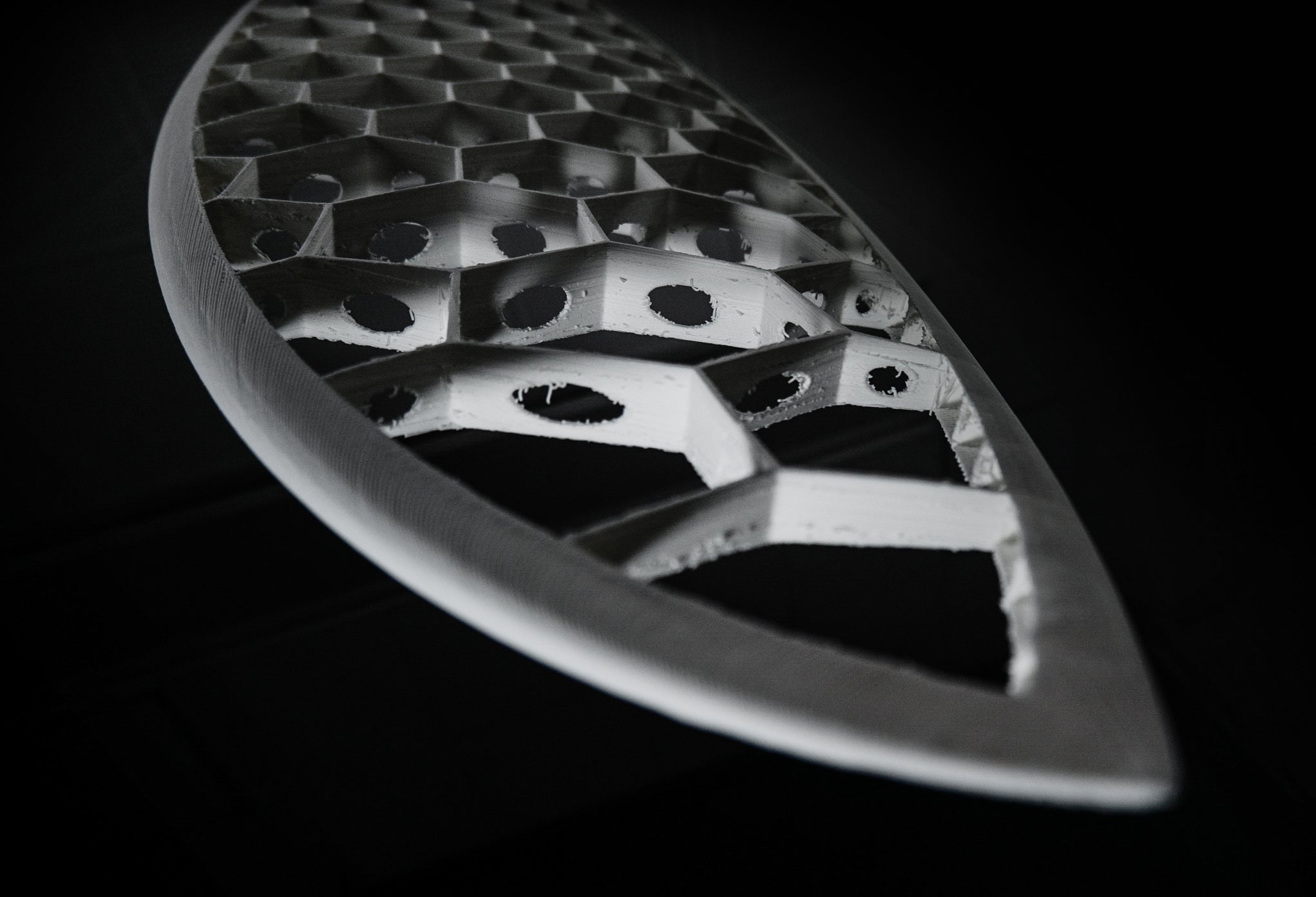

According to our tests with partner laboratories, it takes 3 times more energy to break a WYVE 4DCore skeleton than to damage a Polyurethane soft board (used in 80% of boards on the market). The board is also easily repairable in the event of an impact.

All stages of manufacturing, from 3D printing to finishing, are carried out in our workshop in Anglet. The workshop is open to visits by appointment.