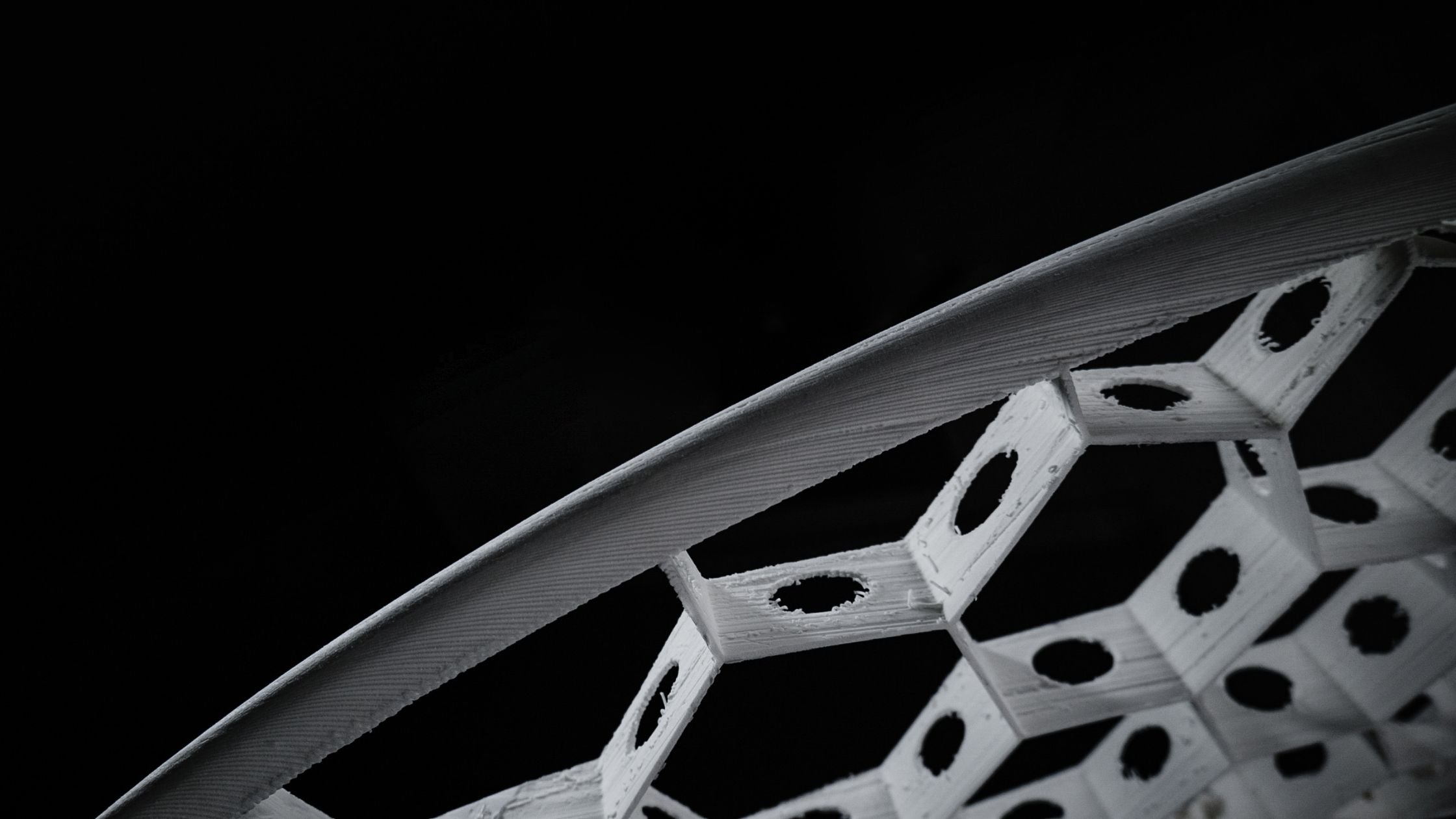

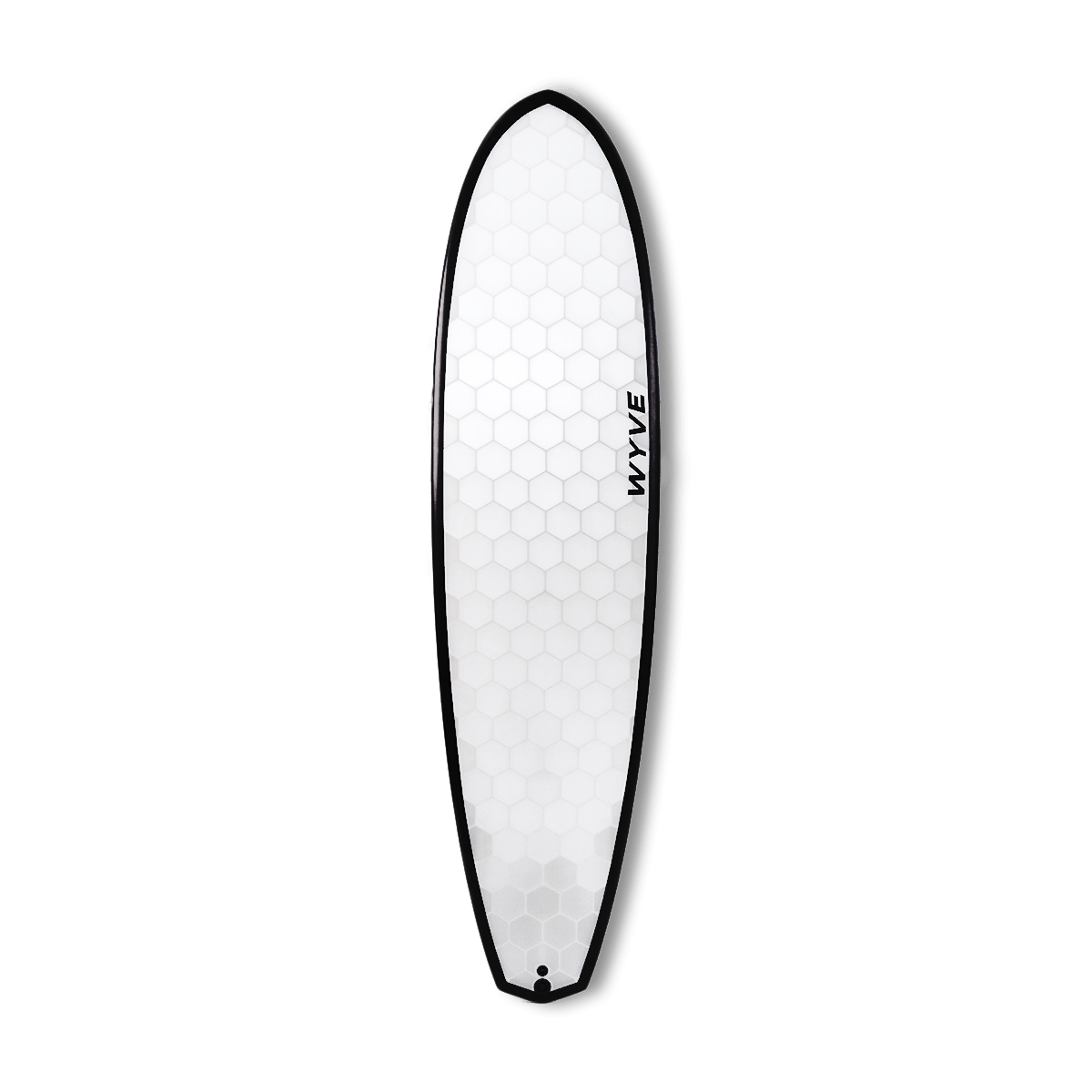

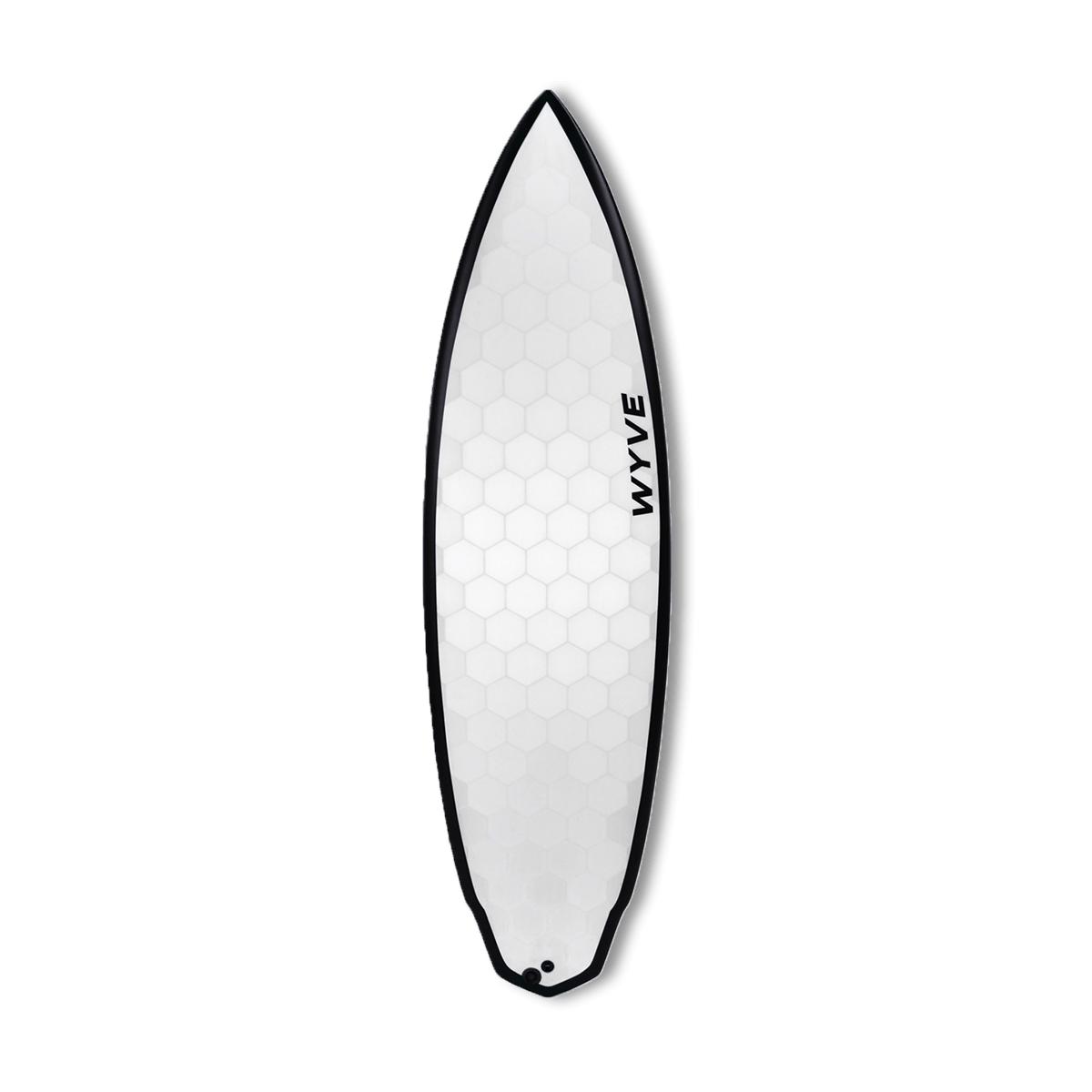

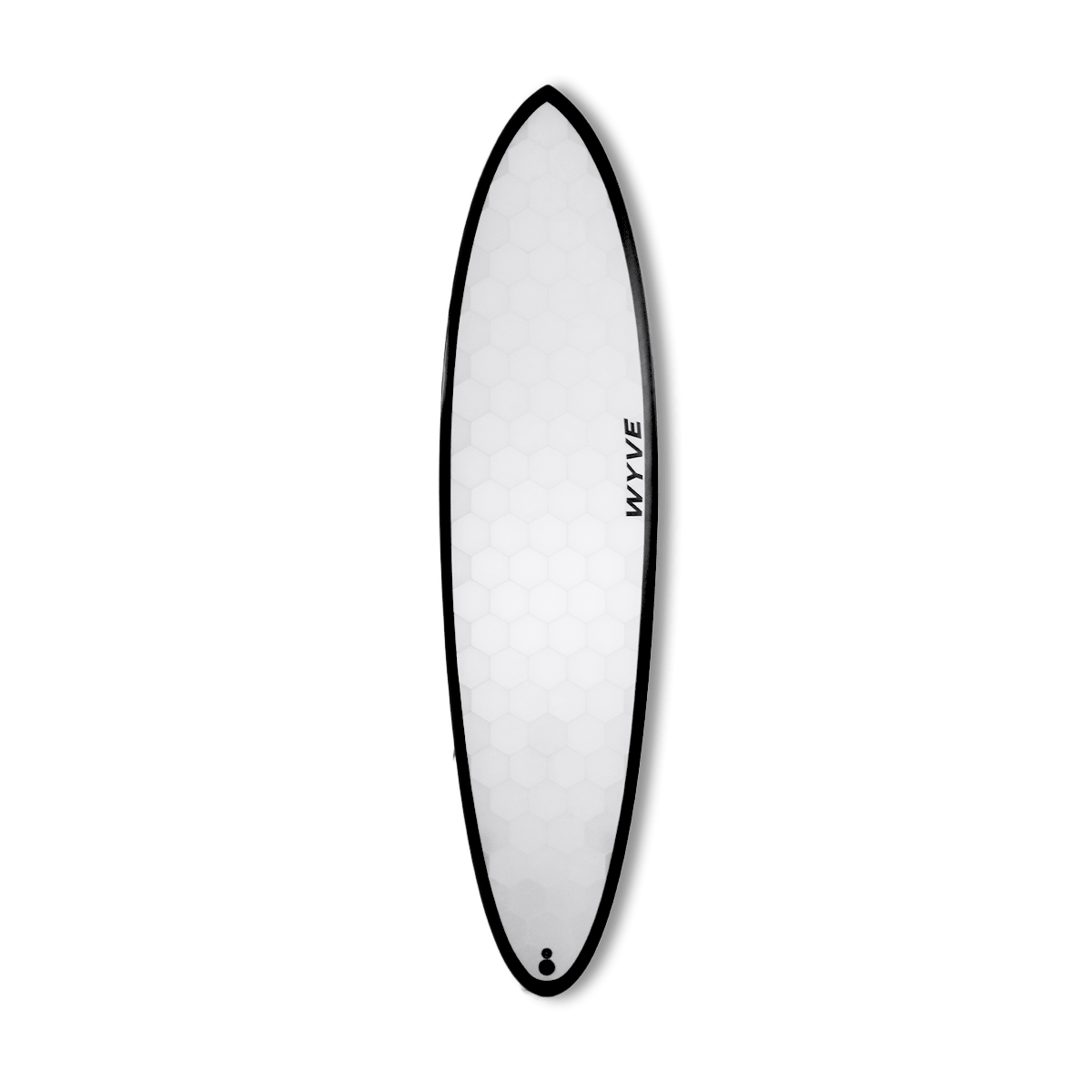

Chez WYVE, nous sommes fiers de créer des planches de surf à la fois performantes et éco-responsables. Notre approche unique de fabrication repose sur l'utilisation de l'impression 3D, ce qui confère à nos planches une solidité et une réparabilité inégalées sur le marché.

According to our tests with laboratories, it takes 3 times more energy to break a WYVE 4DCore than to damage a Polyurethane foam blank (used in 80% of boards on the market).

In the event of a big impact which leads to water infiltration into the board, the water can be drained out using the valve on the tail.

The core does not absorb water, you just need to do a classic repair (epoxy kit) at the location of the impact and the board is like new!

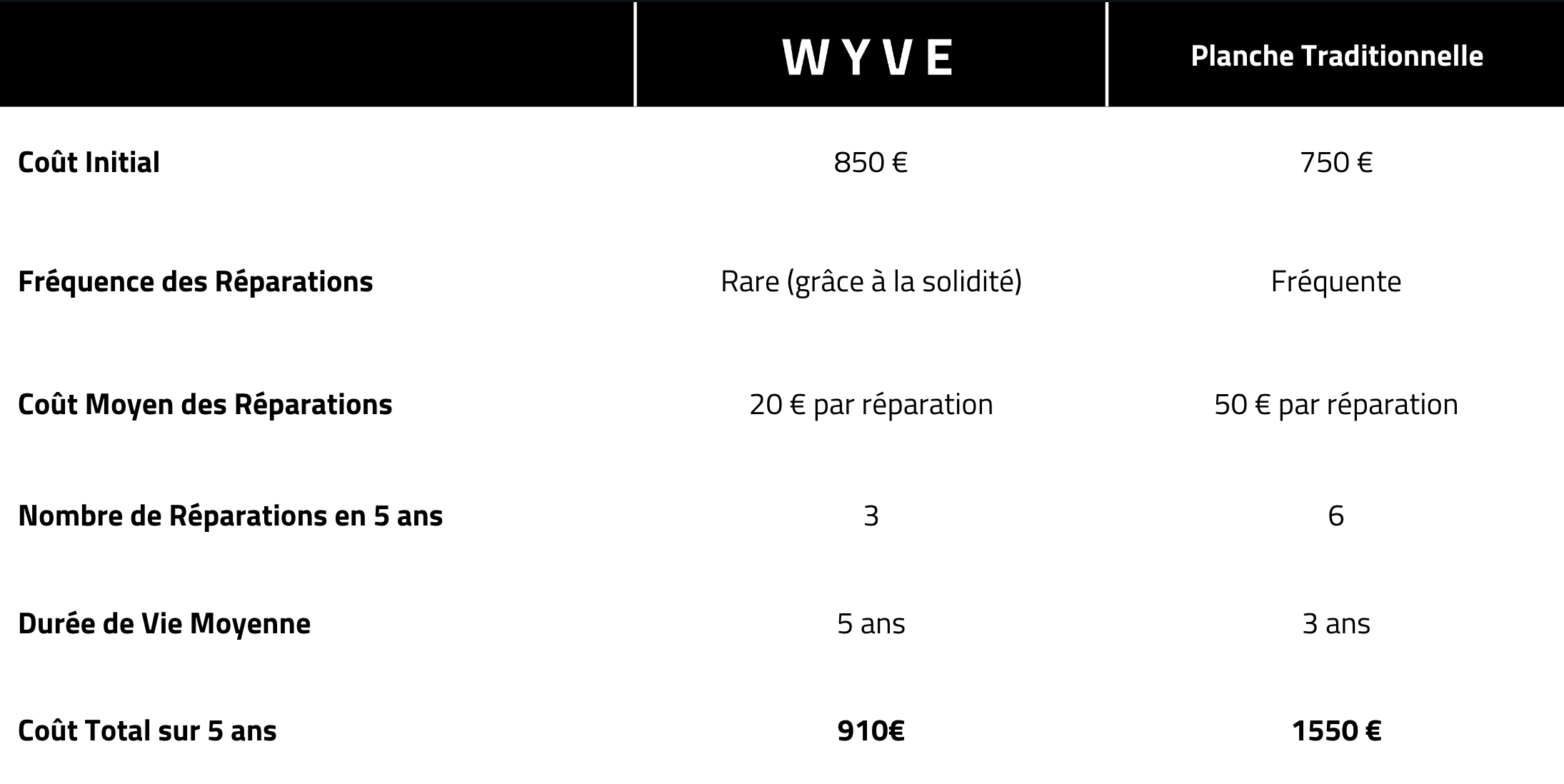

Étude Comparative

Pour illustrer ces points, nous avons réalisé une étude comparative entre une planche WYVE et une planche de surf traditionnelle sur une période de cinq ans :

Ainsi, bien que le coût initial d'une planche WYVE soit légèrement plus élevé, les économies réalisées sur les réparations et la durée de vie prolongée rendent la planche WYVE plus rentable à long terme.

En choisissant une planche WYVE, vous investissez non seulement dans une planche de surf performante et durable, mais aussi dans une solution éco-responsable qui réduit l'empreinte environnementale de votre passion.