By producing surfboards in a sustainable way and limiting waste, Wyve is making its manufacturing process part of a circular economy model.

What is the circular economy and what is its purpose?

The circular economy aims to optimize the use of materials and energy. This model focuses on new ways of designing, producing and consuming, extending the useful life of products, reusing and recycling components.

The objective of the circular economy is to decouple economic growth from the depletion of natural resources by creating positive value loops with each use or reuse of the material or product before final destruction.

The 7 pillars of the circular economy

The seven pillars of the circular economy

How does Wyve fit into the circular economy?

-

Its local and eco-designed offer

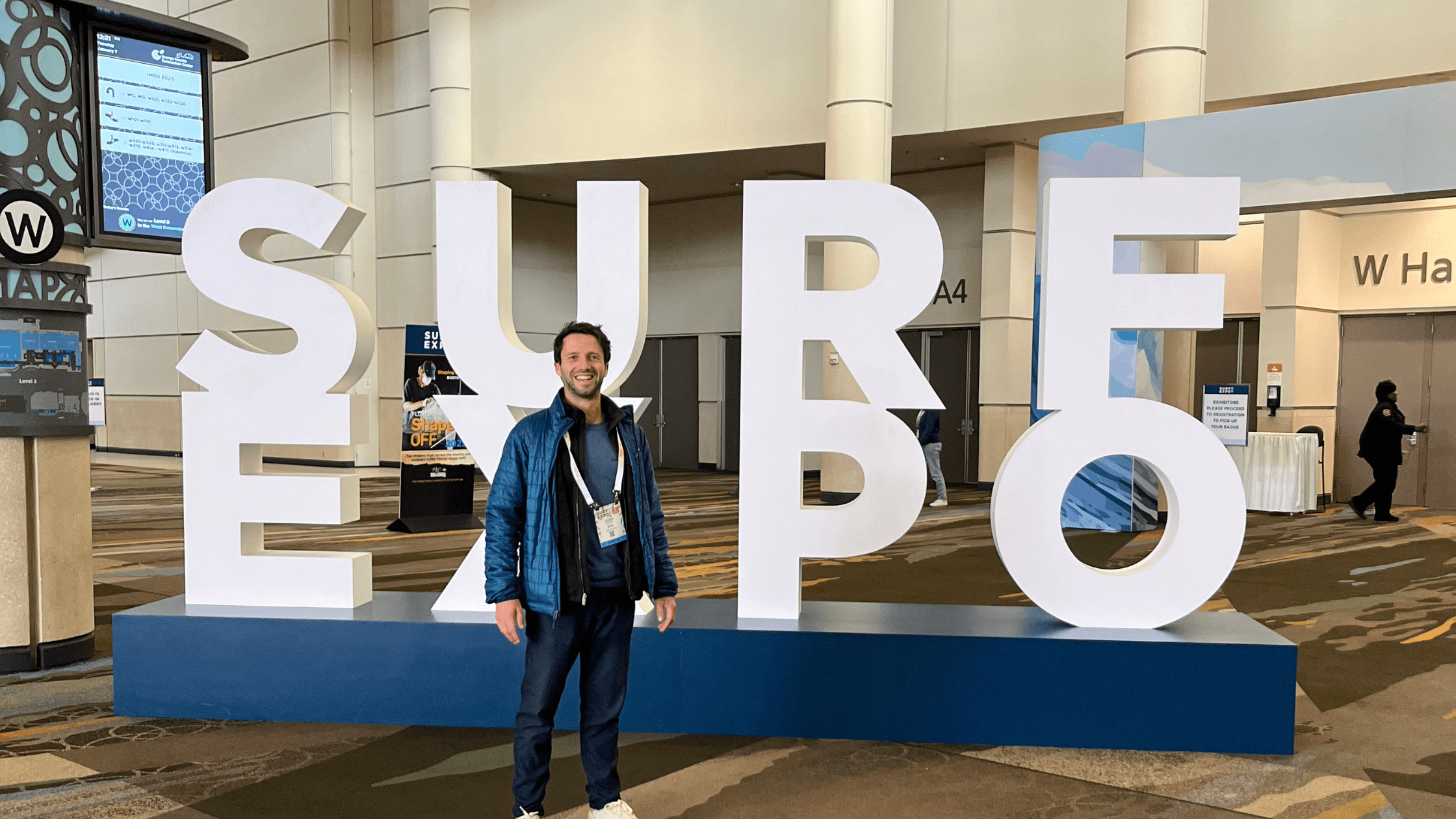

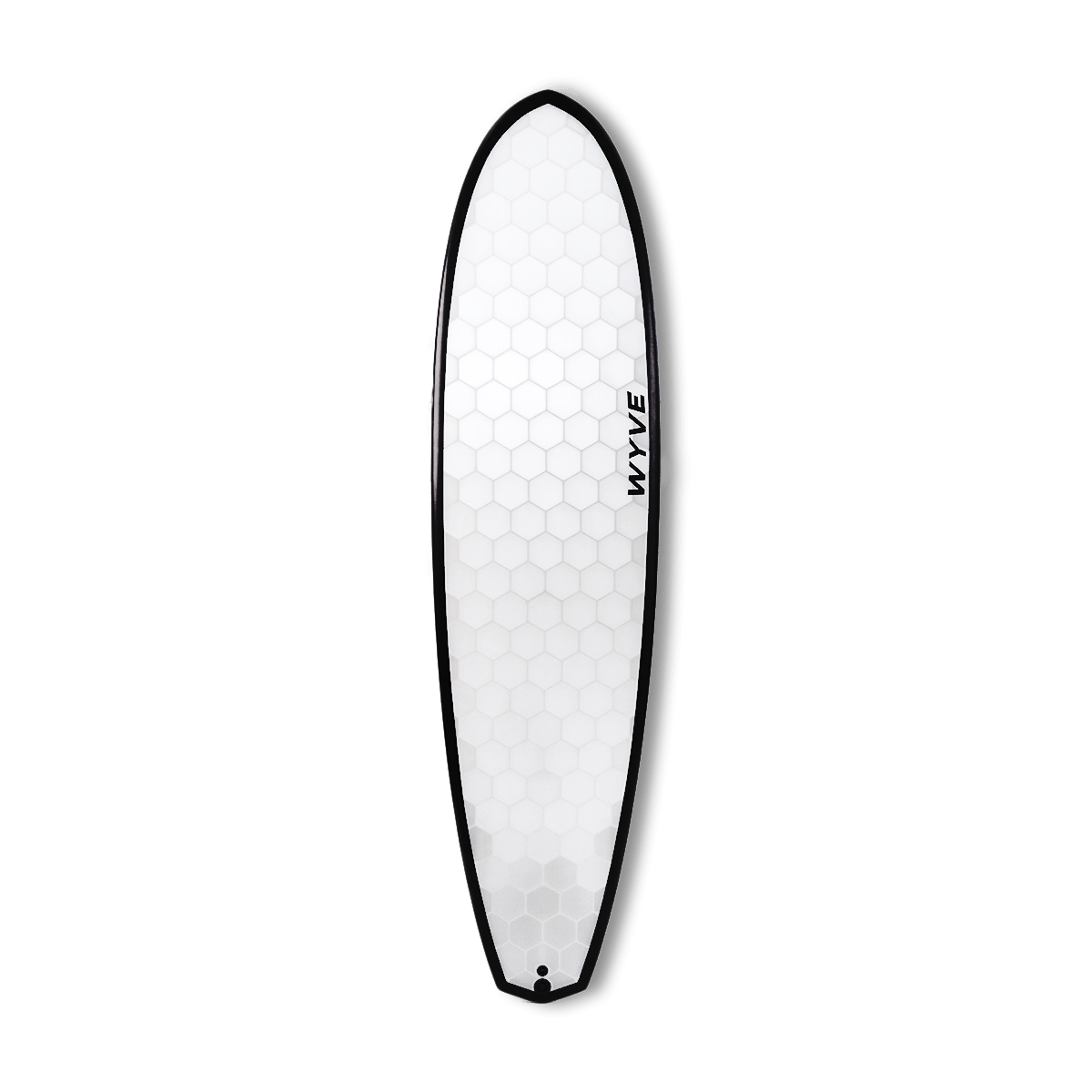

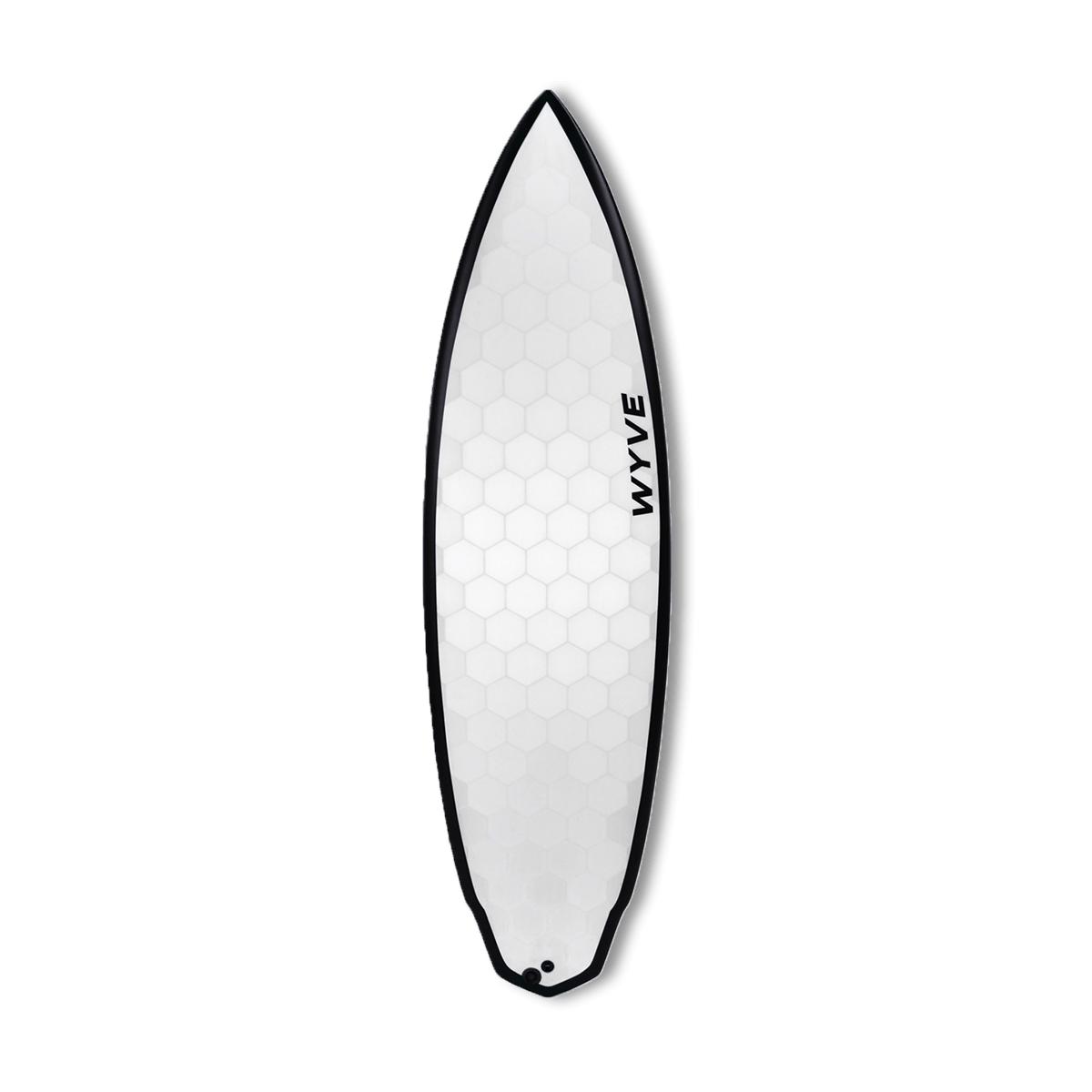

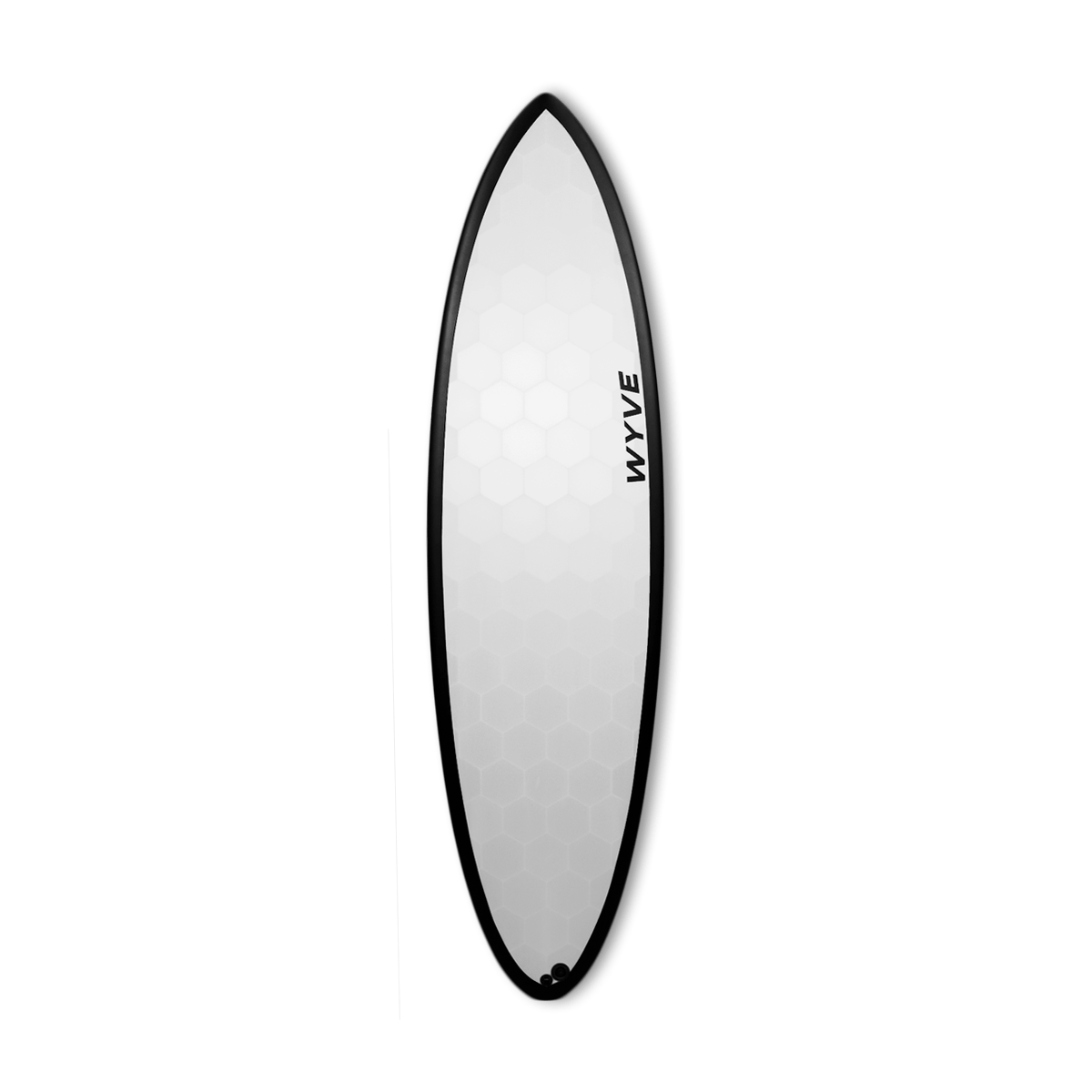

Wyve's goal since its inception has been to minimize the environmental footprint of its manufacturing process. Its local production in Anglet and its eco-designed boards, printed from corn starch, is one of the keys to this model.

-

The demand and the behavior of its responsible consumers

The choice of custom-made boards generates a responsible consumption with the surfer. This approach allows us to respond perfectly to his needs by making him a board adapted to his level and his objectives. This way, we maximize the chances that the surfer will want to keep his board for a long time and the on-demand production avoids overstocking and therefore waste.

In addition, the easy repair of the boards via the decompression valve allows for a longer life span of the product.

-

Its waste management

To go further in the circular economy, the team is working on the 7th pillar of the model: waste management. The goal is to recycle 3D printing scraps in order to use them to print new boards. This circularity allows to optimize the consumption of natural resources.

How does Wyve recycle its 3D printing scrap?

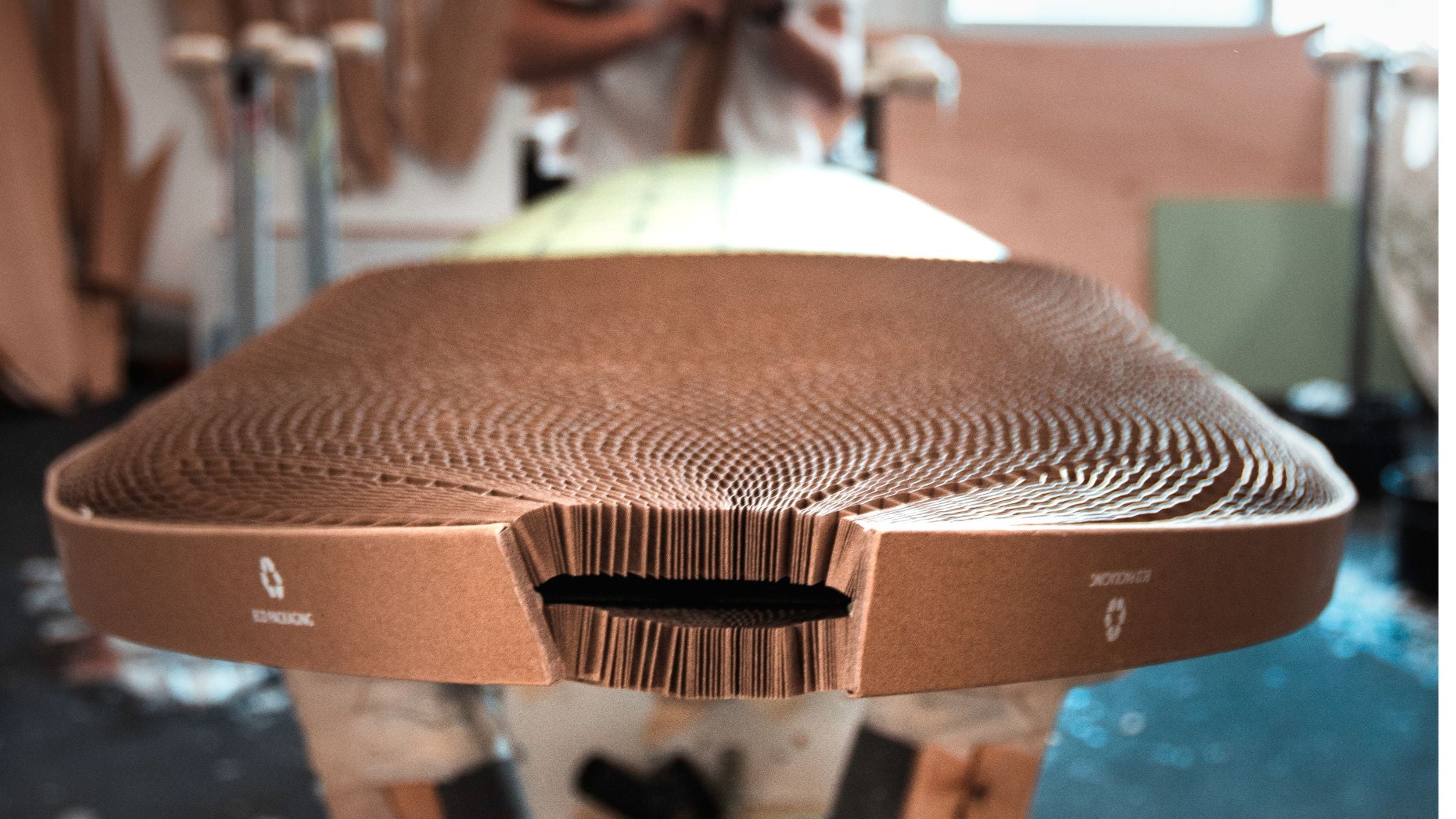

Wyve works in collaboration with the Materials Science and Engineering Department of the University of Bordeaux, whose study project focuses on the recycling of 3D printing filament. This project consists of recovering 3D printing scraps to grind and extrude them in order to recreate a usable thread.

This creates a positive value loop with each reuse of the material.

3D printing scrapstransformed into usable yarn

What are the steps in the scrap recycling process?

Step 1: Grinding - Receiving the PLA material by grinding it into small particles.

Step 2: Drying - The ground material is passed through a drying oven to remove the water contained in it. The oven is an enclosed device in which a predetermined high temperature is maintained in order to perform sterilization of various objects.

Ovening

Step 3: Extrusion - The material then passes into an extruder where it is heated above the melting temperature so that it is fluidized.

Extrusion stage

Step 4: Pelletizing - The material is extruded as a continuous strand and immediately cooled, then passed through a pelletizer to obtain pellets.

Step 5: Oven - Once the granules are obtained, they are put back into the oven to remove the water due to cooling.

Step 6: Injection - Some of the material is kept for injection to create tensile and impact tests to see if the properties of PLA degrade after a certain number of recycles.

The remaining material will go back for another extrusion cycle.

Injection machineused to make the impact and tensile test pieces.

Once all the testing is complete, the recycled PLA is used to create PLA filament to print 3D boards again.

What does the Wyve 3D printing scrap recycling cycle look like?

3D print scrap recycling cycle

After a few months of recycling, what is the conclusion?

Since the beginning of the collaboration, about 15 kilograms of PLA filament has been reformed into usable yarn. This is equivalent to 8 surfboards !

This first solution shows that PLA in its pure state, used for 3D printing, can be recycled. The long-term goal is to meet the following challenge: to recycle an entire surfboard at the end of its life. This challenge is all the greater insofar as PLA is no longer in its pure state, but is in contact with different materials during its life cycle, such as resin, fiber, water... The team is motivated to take up this challenge to propose an ambitious and meaningful alternative vision!